Aircraft Turbocharger - Flying at high altitude has several advantages, such as reduced weight, increased true airspeed, and if pointed in the right direction, higher winds. But there is a major drawback to normally aspirated engines: the lack of oxygen.

As altitude increases, air pressure decreases, and it decreases rapidly. In fact, when you fly at 18,000 feet, 50% of the atmosphere is below you. That means less air for your engine to burn, and a lot less horsepower coming out of the front of your plane.

Aircraft Turbocharger

Turbochargers solve the air problem in piston engines by compressing the intake air before it reaches the piston. By compressing the air, your engine can run as if it is sitting at sea level or below sea level, even if it is running at flight level.

Amazon.com: Pangolin 2359694 235 9694 Turbo Turbocharger For It28g 924g 924gz 928g 930g Aftermarket Part With 3 Month Warranty

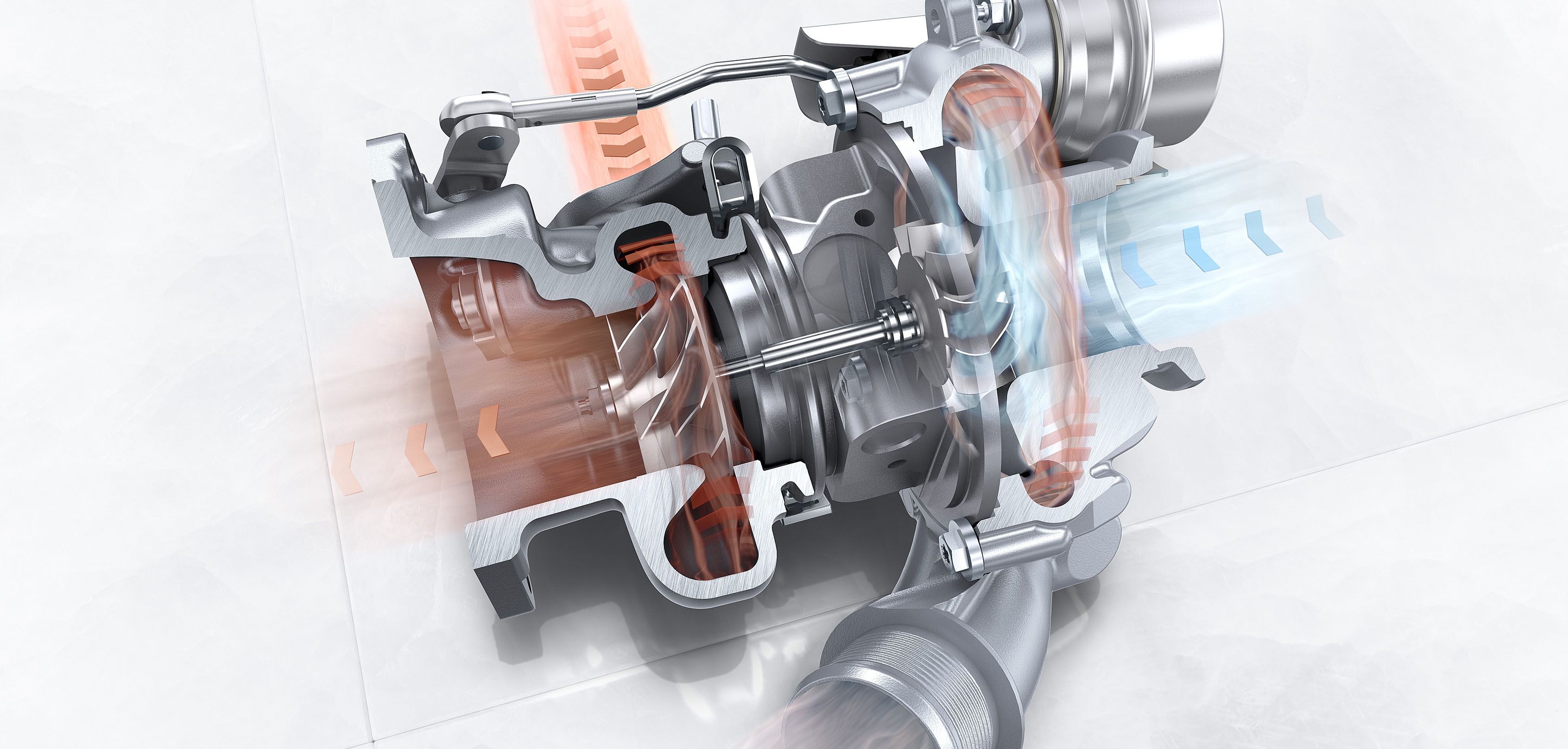

It all starts with a turbine that is driven (turned) by the exhaust gas from your engine. As the exhaust exits the exhaust manifold, it passes over the turbine and spins it. The more exhaust passes through, the faster the turbine spins. That's pretty much how it works, at least for now.

The turbine and the compressor are connected by a shaft, so when the turbine starts turning, when the engine starts, the compressor also starts.

The compressor is responsible for drawing air from the aircraft, compressing it and then moving it to the engine. And as you have already read, the compressor turns because it is connected to the turbine via a shaft.

Turbochargers are good for increasing the air pressure in your engine's intake manifold, known as manifold pressure. But sometimes they are a little too good. Turbochargers can produce excessive pressure that can damage or destroy your engine.

Turbocharger Hi Res Stock Photography And Images

Some wastegates are automatic and others are manually operated by the pilot, but the theory behind it is always the same. The wastegate opens and closes to regulate the amount of exhaust gas that passes over the turbine and prevents the turbine from spinning too fast. The faster the turbine spins, the faster the compressor spins, which means more air gets into your engine.

So how much air can your engine actually take in? It depends on the engine, but there are two main types of turbocharging: altitude turbocharging and ground boost.

Altitude turbocharging, sometimes called "normalizing", keeps your engine running as long as possible as if it were at sea level. It depends on the engine, but most high-altitude turbochargers keep your distribution pressure between 29-30 inches of mercury (sea level pressure) as you gain altitude.

But eventually, as your altitude increases, your turbocharger can't compress enough air to keep your manifold pressure at sea level. This is called the critical altitude, and it is the highest altitude at which your engine can produce the maximum horsepower it is designed for (engine horsepower is rated at sea level).

R (lw12689) Rebuilt Airesearch Te0659 Turbocharger Fits Aircraft Engine

From now on, as you climb higher, less air will enter your engine. That means you will make less horsepower. But it is still much more efficient than a conventional naturally aspirated engine.

Ground boost is similar to altitude turbocharging, but it applies more pressure. Boosted systems typically operate at manifold pressures of 31-45 inches of mercury, much higher than high-altitude turbochargers. The idea is simple. more pressure = more air into the engine = more horsepower.

When you compress air, it heats up. This is one of the biggest disadvantages of any turbocharger. Aircraft engines already run in hot temperatures, and hot air exhaust makes them worse. To solve the problem, many turbochargers use something called an intercooler.

An intercooler is basically a mini air conditioner that sits between the turbocharger and the engine. As the hot air from the turbo moves to the engine, it passes through the intercooler and the temperature drops significantly. The cooler air makes your engine much happier and keeps it running smoothly.

Turbosupercharger Control Systems 2

Turbochargers are key to piston-powered aircraft's ability to climb to high altitudes. Although they add some complexity to the propulsion system, they are the only thing that can bring a piston-powered aircraft for strong tails, higher true airspeed in such scenarios;

Colin is a co-founder and lifelong pilot. He was a flight instructor at the University of North Dakota, a CRJ-200 airline pilot, and led the development of many commercial and military training systems. You can reach him at colin@ Stack Exchange is a question and answer site for aircraft pilots, mechanics and enthusiasts. It only takes a minute to sign up.

Simple question and I always assumed they were the same, but I'd like an opinion from someone who knows more than me :)

They are both internal combustion engines that have a turbine in their exhaust that is used to power a compressor to pressurize the air before it is used for combustion.

Oh Hartzell Turbocharger 46p22250

In a turboprop, the turbine also drives the rep. Between the compressor and the turbine, the fuel/air mixture is burned without significant moving parts. Without a turbine and compressor, a turbine engine is essentially a tube with a heating element inside.

In a turbocharged piston engine you have an otherwise normal piston engine driving the prop. The turbine is located in the exhaust of the rear engine and drives the compressor, forcing air into the rear engine. However, the turbine and the compressor are not connected to the support.

No, a turboprop is more like a jet engine with a propeller in front instead of a fan.

In its simplest form, a turboprop consists of an intake, a compressor, a combustor, a turbine and a propulsion nozzle. Air is drawn into the inlet and compressed by the compressor.

Turbocharger: How Exhaust Gases Increase Engine Power

Many turbo props have a gearbox (as shown in the picture above, black part to the left) that pulls the prop from the engine.

You can learn more about how a turbocharger works at BoldMethod. How does a turbocharger system work? The key is that it uses the engine's exhaust gases to drive the compressor, which increases the pressure (and oxygen content) to enter. More oxygen (and fuel) means more power. For turbos it also means you get sea level performance at altitude.

As for the fuel, the turbo engine runs on Jet-A (kerosene) fuel and (most) turbocharged pistons run on LPG. Some diesel turbos also come from the Jet-A and it is very important not to put the Jet-A in an old gas cylinder or av gas turbo rep.

The advantage of a jet engine over a piston-based engine is power to weight; Well, you have nominally 2 moving parts: the shaft.

Developing Het's Turbocharger Technology

They are completely different things, a turboprop is like a jet engine in that it has compressors, the main difference is that there is a shaft that turns a propeller instead of turning a fan.

A turbocharger is a piece of equipment for reciprocating engines, it uses pressure coming from the exhaust manifold of a reciprocating engine to compress air into the intake manifold. It's the same technology used in diesel and gasoline car engines, and it works the same way. There are paddles that can be adjusted to control the level of boost, on cars they are controlled by a computer, but in many airplanes the turbo speed has to be adjusted manually by adjusting the boost pressure in the exhaust (keyword: waste). However, the latest aerodiesels have modern computerized controls. On reciprocating aero engines, turbos can either be turbochargers, in which they add extra power to the engine by increasing compression in the cylinder, or they can be turbonormalizers, which maintain sea-level air pressure on the engine even at higher altitudes.

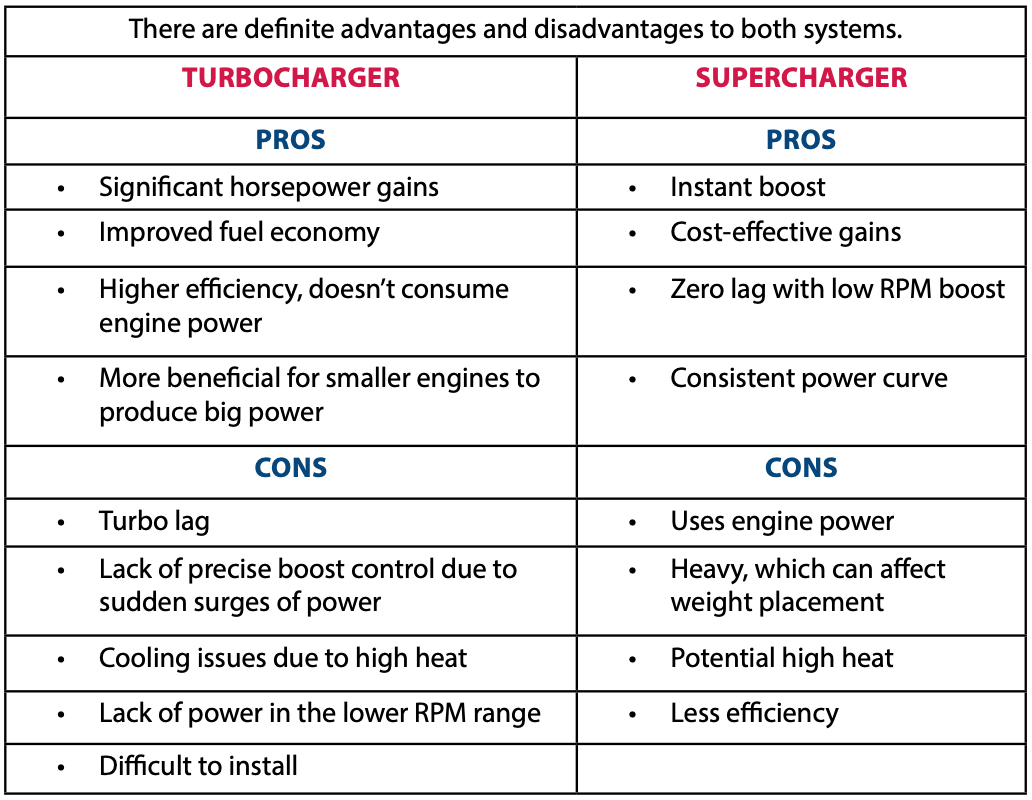

There are also superchargers, these are also compressors for piston engines, the difference is that they use the power of the engine to compress the air directly, not the exhaust pressure.

By clicking Accept All Cookies, you agree that Stack Exchange may store cookies on your device and disclose information in accordance with our Cookie Policy. Members DO more Learn more SAVE more. Get MORE from Being a Pilot - CLICK HERE!

Aircraft And Marine Turbochargers Market Analysis

Internal combustion engines are wonderful things, but for airplanes they have one major drawback. Since they require air to generate power, and the density decreases with altitude, the available power also decreases with altitude. Turbochargers solve this problem.

Turbochargers compress the air and force it into the cylinders creating high thrust. A turbocharger is conceptually simple. Think of a water wheel that is driven by the force of a current. As the water flows faster, the wheel spins faster. In a turbocharger, that "wheel" is in the exhaust stream. Direct contact with the engine in the inlet stream compresses the surrounding air. How compressed the intake air is directly related to the amount of exhaust gases that the system manages through power and exhaust.

The wastegate is a valve that either directs the engine's exhaust via the turbocharger or dumps it outboard. When the wastegate is closed, the engine develops its full power, and when it is fully open, the engine operates more like a normal normally aspirated engine. Waste control is the primary method

Aircraft turbocharger overhaul, cummins turbocharger, turbocharger systems, turbocharger, volvo turbocharger, turbocharger companies, caterpillar turbocharger, turbocharger balancing, variable turbocharger, aircraft turbocharger system, turbocharger shop, cat turbocharger

0 Comments